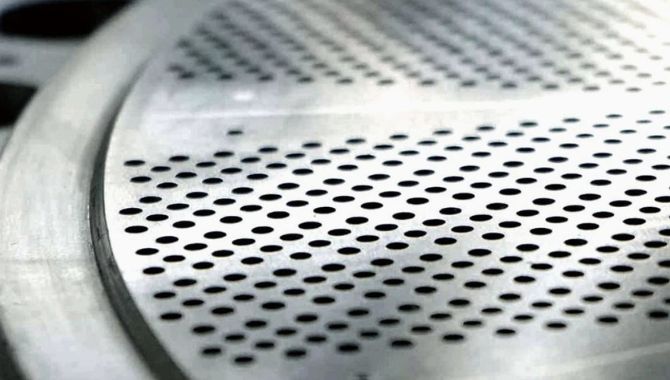

Custom Die Plate For Plastic Pelletizer Machine

DOMIC continue to innovate formwork technology and provide related services. DOMIC specializes in the manufacture and design of formwork. Our pelletizing die plates consist of four main components: the template, the die hole, the heat channel and the pelletizing belt.After extrusion of the high-temperature molten polymer, it is cut into small pellets by a high-speed rotating pelletizing knives.

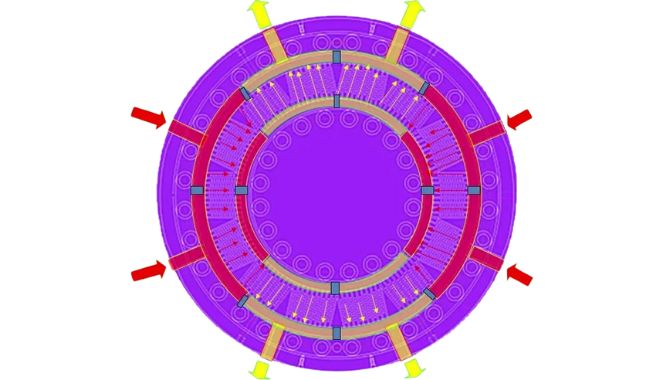

We are constantly developing new materials for pelletizing die plate cutting surfaces, such as TiC-NiC metal-ceramic composites.Technical Advantages: Extended service life, reduced pelletizing template wear, lower pelletizing knives wear.We used finite element analysis Fluent, fluid dynamics and simulation of the temperature distribution. The quality of pelletizing is greatly improved with less temperature difference in the pelletizing zone.

Die Palte Fabrication By Features

Outer Diameter : 1300mm

Number of Holes : 3246

Hole Diameter : 3.5

Production Capacity : 30t per hour

Suitable for Polyolefin : PE

OEM : WP

Outer Diameter : 1263mm

Number of Holes : 5825

Hole Diameter : 2.6

Production Capacity : 43t per hour

Suitable for Polyolefin : PP

OEM : JSW

Outer Diameter : 1208mm

Number of Holes : 4676

Hole Diameter : 3

Production Capacity : 20t per hour

Suitable for Polyolefin : PP

Customized

Advantages of Die Plate

Die plate manufacturing through the ISO 9001 Quality , CE Safety,ROHS Eco-Friendly.

Pelletizing belt using TiC-NiC metal-ceramic composites: wear resistance, heat resistance, corrosion resistance.

Continuous technological innovation, our products are competitively priced.

Improve pelletizing template longevity and reduce replacement frequency.

Brazing

The difficulty in the manufacture of pelletizing die plate lies in the bonding of the pelletizing belt TiC-NiC to thetemplate 1Cr13. The material of the pelletizing belt is welded to the surface of the substrate by means of a brazing process.

Metal Ceramic Composite Material

TiC-NiC metal-ceramic composites, metallographic microstructure, TiC particles uniformly distributed in NiCr, uniform and fine structure, no cracks. HRC: 60~62 Strength: ≥1400Mpa

High Temperature Insulation Gasket

High-temperature insulation gasket, modified PTFE and ceramic materials, fiber materials combined, the heat will be evenly dispersed around the mold hole, effectively prevent heat loss, heat loss rate of no more than 15%.

Heat Channel Design

The pelletizing die plate is heated by heat transfer oil as a heating medium, which enters the hot channel and heats the working area of the pelletizing template.

Why Choose DOMIC to Customize Your Die Plate

-

400,000 tons of PE, granulator CWP, OEM pelletizing die plate test run success: uniform granulation, particle shape regular, smooth surface

-

450,000 tons of PP, granulator Kobe, OEM pelletizing die plate test run success: good granulation, meet customer requirements

We ensure that all our services are of high quality and remain competitively priced. This is what our customers focus on and what we strive for. For your upcoming pelletizing system project, please contact us. Next, we can discuss together how we can meet your needs in terms of pelletizing die plates.