Die Plate For LDPE

| Products: |

LDPE |

|---|---|

|

Number Of Holes: |

1496~3104 |

|

Hole Diameter: |

2.5~2.6mm |

|

Diameter: |

790~1300mm |

|

Production Output: |

200,000~ 400,000 tons per year |

|

CWP Pelletizer: |

ZSK350 ZSK320 |

|

JSW Pelletizer: |

CMP387 CMP335 CMP308 |

|

KOBE Pelletizer: |

LCM450G |

DOMIC Pelletizing Die Plate: Improving LDPE Production Efficiency

In the field of polymer manufacturing, the efficient production of LDPE (Low Density Polyethylene) pellets is ensured by high-quality die plates, and DOMIC has over 20 years of experience in designing and manufacturing high-performance die plates tailored to your needs and adapted to the requirements of many large-scale underwater pelletizers such as the CWP, JSW, KOBE, Coperion, and many others.

The Special Features Of DOMIC Pelletizing Die Plates

Precise Design

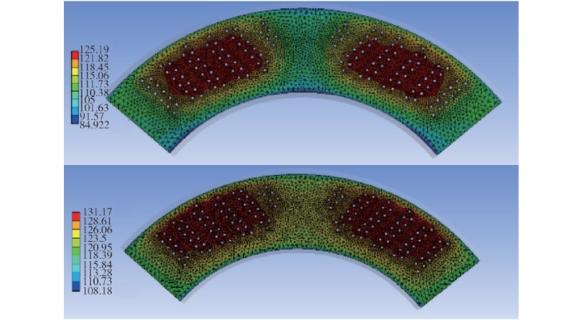

DOMIC’s pelletizing die plates are designed using Finite Element Analysis (FEA) and Fluent simulation technology, simulation and numerical calculations of hydrodynamics, temperature distribution and stress distribution to ensure advanced design and optimal performance of the die plates. Specific embodiment: improve the cooling efficiency of the die plate, optimize the distribution of the die plate’s flow channel, so that the output of the LDPE pellet size and shape is more ideal. Continuously maintain a stable production capacity, and comprehensively improve the operating cycle of the equipment.

Advanced Materials

The structure of the die plate consists of template, die holes, heat channels and pelletizing belts.The pelletizing belts of DOMIC’s LDPE die plate are made of TiC-NiC metal-ceramic composites, which provide excellent abrasion resistance and thermal conductivity under high temperature and high pressure environments.TiC-NiC metal-ceramic composites of pelletizing belts effectively reduce the wear and tear on the pelletizing knives, increase the overall life of the die plate and ensure stable output during use stable output during use. With high loads and high outputs, DOMIC pelletizing die plates can cope with harsh environmental requirements and reduce maintenance and replacement costs.

High Performance And Efficiency

Through the use of Finite Element Analysis (FFA) and Fluent simulation, DOMIC optimizes the polymer flow in the die hole and improves the flow heating efficiency of the thermal oil. It is the refinement and continuous improvement of the design basis that guarantees the output of high quality LDPE pellets. The use of DOMIC die plates has resulted in consistent quality of LEDPE pellets and reduced energy consumption of the equipment.

Long-Lasting And Durable

For more than 20 years, DOMIC has remained advanced in the manufacture of die plates and was the first in the industry to introduce pelletizing belts made of TiC-NiC cermet materials. Our test found that the TiC-NiC metal-ceramic material has the strongest hardness and impact toughness when the TIC content is in the range of 30%~40%. With the application of the new material and new technology, the wear resistance of the die plates is greatly improved, the production stability is stronger, and the replacement frequency is reduced, which prolongs the use cycle.

Operational Stability&Coaching

DOMIC die plates meet industry standards, with efficient heating design and excellent wear resistance, and have exceeded users’ expectations after actual use, so we have been recognized and trusted by many customers.

For example, an LDPE producer in Southeast Asia, after using DOMIC die plates, the production efficiency has increased by 15% and energy consumption has been saved. The high wear resistance of the pelletizing template reduces the number of replacements and maintenance costs by 20%.

LDPE underwater pelletizing technology is demanding. Melt melting index, cylinder temperature, cooling water temperature, equipment installation precision, adjustment and optimization, etc., a detail of the problem will have a great impact on the effect of granulation. The actual production of often tangled knives, trailing particles, particles in bad shape and other sites, our years of research and practical verification, through the optimization of the die plate and the knife with the pelletizer to ensure that the effect of pelletizing.

Exemplary Quality And Durability

With more than 20 years of design and manufacturing experience, DOMIC has accumulated a wealth of experience in the field of pelletizing system. Every piece of our die plates undergoes strict quality control and testing to ensure that the performance meets the use.DOMIC will always be your reliable partner, please contact us now for more information about high performance die plates,let us help LDPE pelletizing efficient production together.