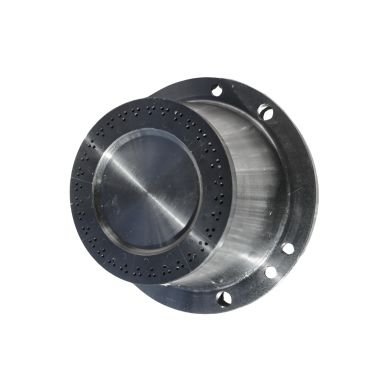

Custom Die Plate For Plastic Pelletizer Machine

DOMIC has been supplying underwater pelletizing die plates to the plastics industry for twenty years with pelletizing rates ranging from 100 kg/h to 9000 kg/h.DOMIC underwater pelletizing die plates are designed to be the most economical product and total solution for our customers.Suitable for a wide range of polymers, offering greater flexibility: a variety of heating methods, a choice of die sizes, different materials for ranulation belts, and more. Achieve lower costs and uniform pellets that meet customer specifications.

Our experience and commitment to our customers is the basis for success.

Die Palte Fabrication By Features

Outer Diameter : 282mm

Number of Holes : 180

Hole Diameter : 2.8

Production Capacity : 4t per hour

Suitable for Polymers : TPU

OEM : MAAG,AUTOMATIC

Outer Diameter : 143mm

Number of Holes : 32

Hole Diameter : 2.6

Production Capacity : 3t per hour

Suitable for Polymers : POE TPU

OEM : BKG

Outer Diameter : 143mm

Number of Holes : 64

Hole Diameter : 3.5

Production Capacity : 5t per hour

Suitable for Polymers : PLA

Customized

Outer Diameter : 143mm

Number of Holes : 96

Hole Diameter : 1.8

Production Capacity : 2t per hour

Suitable for Polymers : TPU

OEM : BKG

Advantages of Die Plate

Triple international certification:ISO 9001 Quality,CE Safety,ROHS Eco-Friendly.

Pelletizing die plates are custom designed to your specific process requirements.

Competitive pricing programs that take into account the lifecycle of the die head.

Different polymers are characterized by different die plate solutions.

Experienced In Design And Manufacturing

DOMIC pelletizing die plates are custom designed to meet each customer’s specific polymer requirements. Granulation belt surface material, number of holes and heating method, and different polymer properties dictate different options.

With over 20 years of production experience, we can provide data references to ensure a suitable solution. This is our best area of expertise.

Brazing

The difficulty in manufacturing pelletizing die plates lies in the bonding of the granulation belt to the template.

The material of the granulation belts is welded to the surface of the template by means of a brazing process. The high quality of the brazing technology determines that the granulation belts do not come off and ensures a long service life.

Cost-Savings

Thanks to more than 20 years of technological precipitation, our pelletizing die plates are comparable to the quality of products from well-known suppliers in Europe and the United States, and our advantage is that the price is more reasonable, so that you have a higher rate of return. Compared with European and American products, we save more than 50% of your investment.

Why Choose DOMIC to Customize Your Die Plate

- POE, pelletizer BKG, OEM template test run success, to solve the pelletizing blocking holes, bad material shape

-

TPU, pelletizer MAAG, OEM template test run success, electric heating changed to oil heating, improve yield, granulation uniformity, particle shape regularity

We continue to innovate in moldboard technology and provide related services. Technical advantages: longer service life, less wear on the granulation belt, lower pelletizing knives wear. We ensure that all our services are of high quality and at competitive prices.