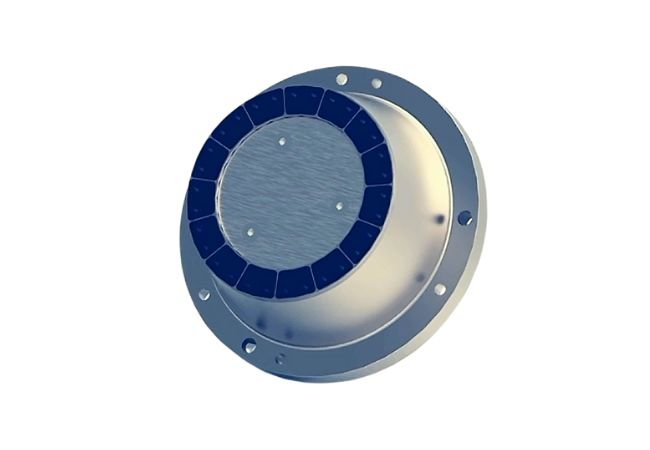

Die Plate For TPU

| Products: |

TPU |

|---|---|

|

Number Of Holes: |

30~120 |

|

Hole Diameter: |

2~3.5mm |

|

Diameter: |

120~320mm |

|

Production Output: |

30~ 4000 kg/h |

|

MAAG Pelletizer: |

PEARLO |

|

BKG Pelletizer: |

AH、AH D |

Software Simulation

For TPU pelletizing, the extruder kneads the molten TPU and outputs it to the plastic pelletizer machine. In the pelletizing system, the molten TPU is extruded through the die plate, quickly cut off by the pelletizing knife inside the water chamber, cooled down in the cooling water to form pellets, and brought to the dryer through the circulation system. For perfect pellets, the temperature, flow rate and pressure must be controlled at each stage.

DOMIC Die Plates use Finite Element Analysis (FEA) and Fluent Simulation to simulate the use of additional insulation in the template cavity in the pelletizing system to ensure that the design is optimized for optimal use.

Superior Thermal Insulation Structure

The thermal insulation structure provides a stable temperature environment when the molten TPU is output on the pelletizing surface. Low thermal conductivity ceramic material on the outer layer, air sandwich in the middle layer and high thermal conductivity metal coating on the inner layer. Enhancing the overall fluidity of molten TPU in the die plate ensures uniform temperature distribution in the die holes and smooth and stable output in order to ensure optimal pelletizing granules.

Minimized Effects Of Thermal Stress

DOMIC reduces thermal stresses in the pelletizing system and has high fabrication standards. Selection of low coefficient of expansion high temperature alloy Inconel 718. design of 2 to 3 layers of step holes to avoid stress concentration. Nitriding of the surface layer of the die plate to protect the surface layer from micro-cracks. Provide the best environment for pelletizing surface and pelletizing knife.

Advantages Of Cleaning And Washing

To solve the pain point of die plate cleaning, TPU production is characterized by many varieties, small batch, and sticky materials. Factories generally use small extrusion pelletizer, frequent switching between different materials or different grades, while the die plate needs to be cleaned and washed. Conventional use of vacuum sintering. In addition to the selection of low coefficient of expansion of high temperature alloys, DOMIC in the pelletizing surface and die plate body of the weld to make greater improvements to ensure that the welded position, repeated sintering does not crack.

High-Performance Heating Methods

The pelletizing system of plastic processing equipment usually has three kinds of heating methods: electromagnetic heating, electric heating tube heating and thermal oil heating. Electric heat pipe heating: applicable to a variety of die materials, easy to install and maintain, but slow warming, short life, low thermal efficiency, currently belongs to the elimination of technology. TPU in the pelletizing process is highly sensitive to the temperature. TPU pelletizing template heating methods: electromagnetic heating or thermal oil heating.

Electromagnetic heating: fast warming, uniform temperature control, no overheating and overcooling position. But the temperature control in the extrusion position is not accurate. Matching cost is high, not suitable for stainless steel material.

Heat-conducting oil heating method: precise temperature control, precise control of the heating position. Especially in the production of high viscosity TPU applications, reduce the uneven stability of the fluidity of the pellet quality problems caused by the pelleting, pelleting the appearance of the pellet to improve the larger.