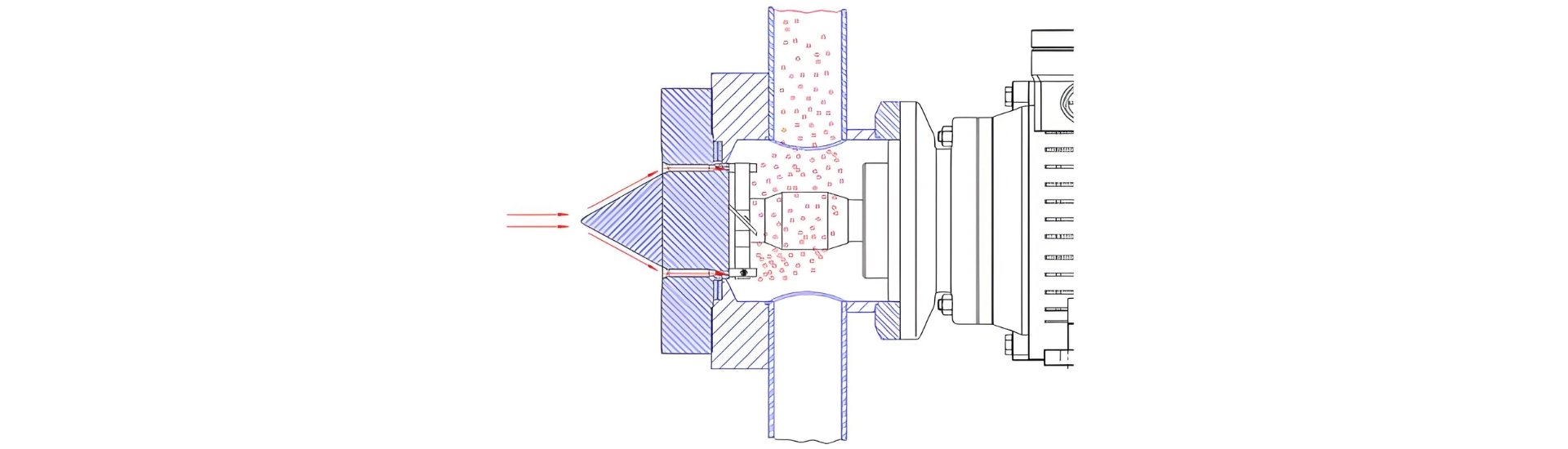

Pelletizing die plate comprises four primary components: template, mold hole, hot channel, and granulation belt.

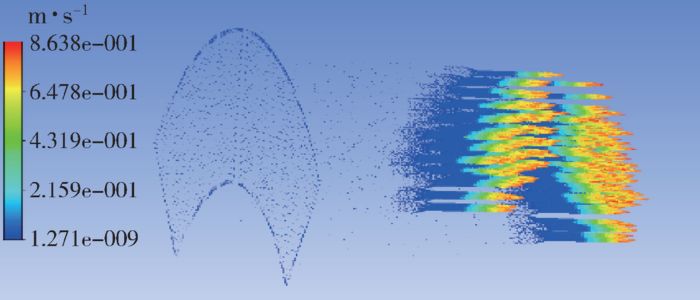

A viscous plastic fluid in a molten state is driven by the extruder screw or melt pump into a closed pelletizing die plate cavity heated to a specified temperature.The expanded surface of the molten plastic is instantly cured by the rapid cooling of the pellet cooling water at the appropriate temperature on the surface of the pelletizing die plate through the reduced-size outlet holes.

When the surface-cured plastic is continuously generated to a specified length, the pelletizing knives, which are parallel to and in close proximity to the granulation belt, shear the plastic with the cooperation of the pelletizing die plate discharge holes to generate pellets within the specified range.The generated pellets are transported along with the cooling water to the downstream equipment, where the pellets are dried and screened, thus completing the pelletizing process for plastics production.